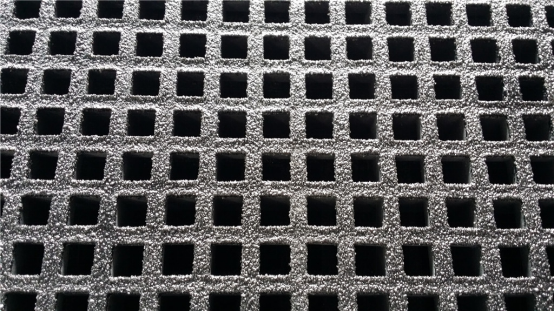

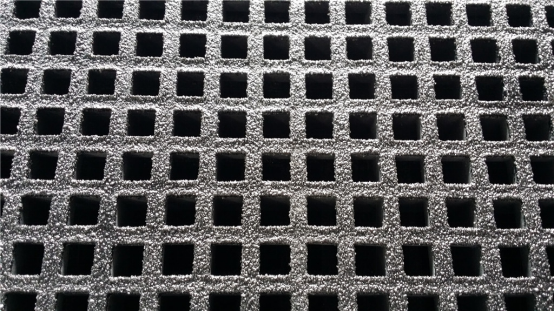

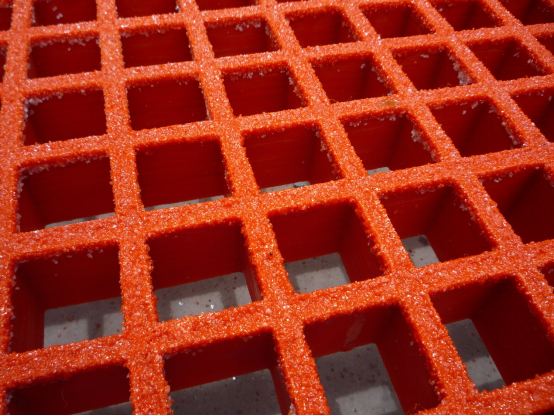

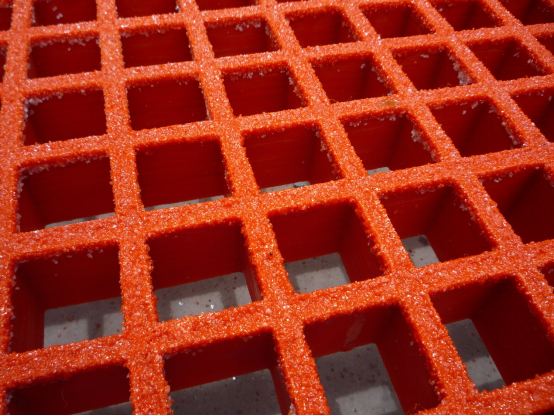

Molded grating is manufactured in an open, heated mold system. Continuous E-glass roving's are placed in the mold in alternating layers and completely wetted out with resin. This continuous process produces an integral, one piece construction which provides excellent corrosion resistance as well as bi-directional strength. There are a number of different molds available resulting in a extensive range of panel sizes, thickness and mesh patterns.

FRP/GRP molded grating for ramps, walkways, platforms and washbays. It has an anti slip surface in wet, oily and icy areas. Industrial GRP grating is light, strong, easily installed and available in all sizes, thicknesses and fixings are also stocked.Often referred to as GRP grating and a great alternative to steel gratings, (glassfibre reinforced plastics) this material is generally know a the material for the construction of chemical plantand yachts.Anti Slip Grid Floor Grating - Anti slip surface for health & safety requirements,Anti slip Grid Flooring - slip resistant to suit industrial flooring applications. fixings available.

Industries

¡ñ Chemical plant and metal finishing;

¡ñ Construction engineering, traffic and transportation

¡ñ Petrochemical engineering, ocean survey, water engineering

¡ñ Food and beverage plants

¡ñ Textile printing and dyeing and electronic industryX5H(26W)13XN.png)

¡ñ Chemical plant and metal finishing;

¡ñ Construction engineering, traffic and transportation

¡ñ Petrochemical engineering, ocean survey, water engineering

¡ñ Food and beverage plants

¡ñ Textile printing and dyeing and electronic industry

X5H(26W)13XN.png)

Functions£º

¡ñ Anti-slip floor, stair tread, foot bridge

¡ñ Operation platform, trench cover

¡ñ Security and safety fence, handrail

¡ñ Off-shore oil rig, moor shipyard, shipping deck, ceiling

¡ñ Ramp ladder, scaffold, railway footpath

¡ñ Decorative grid, man-made fountain pool grid

¡ñ Non-conductive and non-magnetic

¡ñ Anti-slip floor, stair tread, foot bridge

¡ñ Operation platform, trench cover

¡ñ Security and safety fence, handrail

¡ñ Off-shore oil rig, moor shipyard, shipping deck, ceiling

¡ñ Ramp ladder, scaffold, railway footpath

¡ñ Decorative grid, man-made fountain pool grid

¡ñ Non-conductive and non-magnetic

Advantages£º

¡ñ Anti-fire

¡ñ Anti-corrosion and anti-aging

¡ñ Anti-slippery

¡ñ Light but high loaded strength

¡ñ Long service life and maintenance free

¡ñ Non-conduction or magnetic

¡ñ Easy installation and rich colors

¡ñ various sizes and colors available

¡ñ Anti-fire

¡ñ Anti-corrosion and anti-aging

¡ñ Anti-slippery

¡ñ Light but high loaded strength

¡ñ Long service life and maintenance free

¡ñ Non-conduction or magnetic

¡ñ Easy installation and rich colors

¡ñ various sizes and colors available