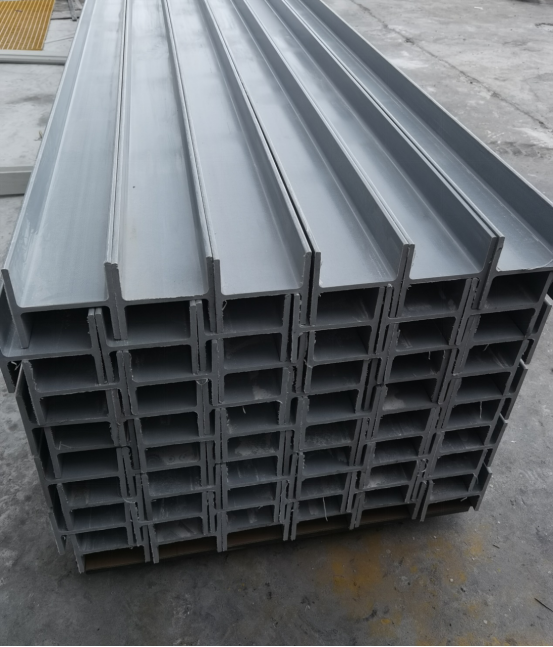

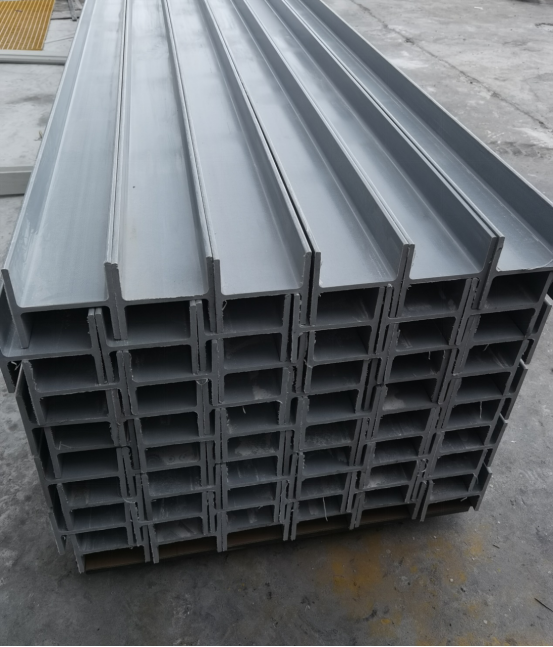

Pultruded Fibreglass Profiles are manufactured by combining various resins with pure glassfibre reinforcement. They are formed and cured in a continuous process creating a product of extraordinary strength and resilience. The resultant Pultruded Fibreglass Profile offers a combination of benefits and mechanical properties exceeding those of metal.

Pultruded GRP Profiles

The Pultruded GRP Profiles provide exceptional strength, toughness and consistency. Pultrusions offer a number of advantages over traditional materials such as steel, aluminium and timber and their use is increasing across a wide range of applications and industries.

The almost infinite variety of possible Pultruded GRP Profiles allows a high degree of design freedom. Tailored properties such as strength, stiffness, weight and colour can be engineered by product design at the early stages of development.

Pultruded Profiles

On a weight to weight basis, Pultruded Profiles are stronger than structural steel. By varying the type and orientation of the reinforcements, various mechanical properties can be obtained and tensile strengths in excess of 1000 MPa are achievable. Considerable design freedom can be gained by the capability of adding extra strength in highly stressed areas. The excellent impact strength of Pultruded Profiles can reduce damage potential caused by accidental collisions.

Benefits of Pultrusion

The Fibreglass Pultrusion process provides exceptional strength, toughness and consistency. Pultrusions offer a number of advantages over traditional materials such as steel, aluminium and timber and their use is increasing across a wide range of applications and industries. The almost infinite variety of possible profiles allows a high degree of design freedom. Tailored properties such as strength, stiffness, weight and colour can be engineered by product design at the early stages of development.